Desert_Sky

Since 1998

brotherhood, you got yourself a damn fine looking rig there. how do those dual display controllers work?

brotherhood, you got yourself a damn fine looking rig there. how do those dual display controllers work?

Here you go...

I can attach this to a return in the lid if I want to fly sparge via a male compression fitting at the end of the return.

This arm just has a male compression fitting and then a spinning union to it can spin with some pressure. I'll try to post a You Tube video in the neat future.

I drilled 6 holes in each arm to give it some directional pressure so it spins.

I'm having a hard time deciding how to handle the lid returns. In the BYO article, Lonnie describes his method of recirculating the HLT to itself and the MLT to itself until the mash runnings are clear, the flow rates are equalized, and its time to start sparging. At that point, he simultaneously moves the MLT lid to the boil kettle and the HLT lid to the MLT. This starts the process of draining the mash runnings to the boil kettle and starting the sparge.

It doesn't really matter what kind of return is on the HLT. You could have a mash-suitable return on your HLT and MLT lids so that when you shift the lids over the mash continues to get the benefit of an appropriate non-channeling return. It might be a copper tube with holes drilled in it, or a spinning sparge arm, or a stationary copper pipe return designed to sit on top of the grain. Any of these would cause HSA as wort splashes into the boil kettle when you shift the MLT lid over to it, right? Or is that irrelevant since it is pre-boil? Also, a mash-suitable return wouldn't be the best when you are recirculating wort through your plate chiller post-boil to cool it. You could clog it up with break material and hop debris that made it past your siphon screen.

Those of you who do the lid swapping routine, what solutions have you come up with? I thought about adding quick-disconnect fittings on top of the lids and just swapping hoses, but that means you'd have to stop your pumps and resynchronize the flow rates. Still, that might be a better solution since you could then have a return on the underside of each lid that is appropriate for the kettle it belongs to.

This is pretty close to what I do, I have a cork screw shaped return circle, when throttling the return valve , I can maintain water on top of the grain bed ( to prevent drilling ) and get a nice recirculation of wort going. My lids like Korndog don't move position, the water in the HLT stays put, although with my cleaning mode, I can utilize that hot water to clean and recirculate sanitized water throughout the whole system or to clean carboys/cornys.Here is what I do:

1. I have an "H" shaped return manifold for the MT that is on a long piece of copper so that it is height adjustable through a drilled out compression fitting. I switch this lid to the boil kettle where I lower the manifold to the bottom of the kettle to avoid HSA splashing. I pump at a resonable rate of speed to avoid same.

2. My HLT return is simply a flexible stainless steel tube which never leaves the HLT.

3. My boil lid has another flexible return with a nozzle, which serves as a whirlpool arm and again is not used on other vessels.

Photos in gallery.

KD

That helps me quite a bit, KD. Your MT lid is only used on the BK for delivering the wort, and you use your dedicated BK lid later for whirlpooling/recirculation.

I like your adjustable height copper tube MT manifold. That's a great idea to use the compression fitting. Wouldn't it work just as well with a plain hole in the lid? The manifold is either going to sit on top of the grain or at the bottom of the BK, so it doesn't need any tensioning.

I take it you are batch sparging? If you were fly sparging with the lid setup you described, I'd think you'd need another adjustable manifold lid to get water from the HLT to the MT while you're pumping your wort out the bottom of the MT to the BK.

Here's a picture. Yes, it's a little tweaked. Sorry about my wife getting in the way of the picture.

Nice, KD. And that's not a bad looking copper manifold either.

Nice, KD. And that's not a bad looking copper manifold either.

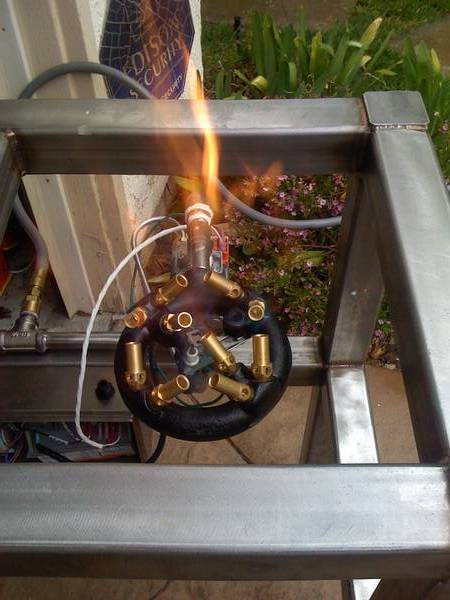

Well I'm pretty pleased. I got my first spark fired burner up and running! It's very cool.

ok i haven't got all the way thru the thread yet but how did you set up the spark ignition module? where and what type of parts did you get, do you have any model numbers? That looks like a nice idea to further automate things!!

Thanks

korndog,

What was the source of your stainless flex line used in your lids? I've found several with stainless flex but brass ends. Yours seem to be 100% stainless.

Thanks...

I know you guys are all done but I thought I would post a pic of where I am with mine. Here is the stand wich i cleaned / primed / primed / primed / painted / painted / painted.

I have my asco's, my ball valves, and my burners. If i can run to the store this weekend I will try to get them assembled to the stand. I was wandering if i should paint my gas lines like red or greeen or something. I havnt decided yet.

I am going to build my pilot system like lonnie mac did. Im no good at wiring all this stuff up and while this method isnt the preferred, Its cheaper and I will be minding the brew anyway as I brew in my party garage.

I know you guys are all done but I thought I would post a pic of where I am with mine. Here is the stand wich i cleaned / primed / primed / primed / painted / painted / painted.

I have my asco's, my ball valves, and my burners. If i can run to the store this weekend I will try to get them assembled to the stand. I was wandering if i should paint my gas lines like red or greeen or something. I havnt decided yet.

Are you going to be doing the control panel, too? If so how do you plan on mounting it? I'm thinking of building one of these myself and am looking for ideas.

is there a reason why the boil kettle is always on the left and the HLT on the right?

http://https://www.homebrewtalk.com/f11/review-my-brutus-clone-82652/a linke to a post i made with CAD screengrabs of my plan.

I plan on adding a rotationg arm on the control panel so that I can get it out of the way when Im finished brewing.

The brutus 20 apparently gets poor efficiency

You would have to up your grain bills accordingly.

I thought I read somewhere it was 74% I could be wrong though

OK here are some pics of my build so far,

I know its not great, but hey its mine.

Thanks to KornDog for all the help with this, without his help there is NO way I could have done it.

The control panel is pretty straight forward, 2 PID temp controllers, 2 timers, 2 lighted pump switches, and 1 main power lighted switch.

Its still not done but hey, is brewing gadgetry EVER done?

so without further adoo,

74% is POOR efficiency?

Enter your email address to join: