Displaced MassHole

Well-Known Member

yep. i get an initial kind of pop then a low frequency hum the whole time it's energized

Sweet, glad its not just me. Thanks Chimone--

yep. i get an initial kind of pop then a low frequency hum the whole time it's energized

I assume he is talking about 1/4" o.d. refer tubing which is hand bendable.

Good idea on the extra stability. I haven't had an issue yet, but then mine hasn't been transported to an event yet either. I had a leak in on of my welded joints too. JB Weld fixed the pinhole with no issue.

So my question is what kind of paint/primer did you guys use? I figure ill have to scrub the entire stand with something to remove the oils on the metal, then prime it and then put a High temp resistant paint. Im just not sure what kind would be best for the application.

SWMBO Surprised me with my wedding present. She had my stand welded for me.

Theres not a way to rewire it to make it work?

Theres not a way to rewire it to make it work?

First. Those valves are 0-125. they are fine. I think you CAN use normally open valves. I think you just have to set your Love for cooling instead of heat.

If you have the 2008+ Love switches, I think you can just wire to the NC terminal instead of NO and be good to go. You will have continuity when the controller is powered, which will close the valves. You would just program for heat like normal.

One way or another, you will be able to make them work. You just might have to turn your gas off before you power down the controller.

2008+ meaning built this year right? not a new model or anything? I may be able to contact Love Controls and ask them the best way to make it work with my situation and see what they say. Id hate to just sit here and stare at those valves.. If i have to I may be able to find someoen to buy the and buy the STC valves. I think i can get 2 of those for $88 Shipped

woohoo

this is hilarious. My welder was just over here picking up a keg when we got to talking. Aparently my Brutus was built with 2x2x1/4 Haha I thought I had 1/8" this whole time but its a quarter inch instead. I thought it was pretty damn heavy

woohoo

this is hilarious. My welder was just over here picking up a keg when we got to talking. Aparently my Brutus was built with 2x2x1/4 Haha I thought I had 1/8" this whole time but its a quarter inch instead. I thought it was pretty damn heavy

LOL, talk about overkill. I'm quite sure 1x1x1/8 would be plenty strong.

After comparing 1/8" & 1/16" at a metal supplyer here I ended up deciding on using 2x2x1/16"... I'm probably going to add a couple of vertical braces on the back side just to make myself feel better about it.

I felt that doing 1/8" was going to make for one heavy stand.

dWiGhT

Hello:

I'm in the process of planning a Brutus 10 build.

I'm trying to decide on going with the 60 qt. Megapots, but don't know if they will fit on the structure using Lonnie's plans.

Can anybody chime in on what they're using and whether Megapots will work?

I've also found a 60 qt. ss kettle on Amazon that 17 3/4" dia. for a great price, but I think it's too big?

Thanks in advance for any info. provided.

Great thread and forum by the way

~Rob

Hello:

I'm in the process of planning a Brutus 10 build.

I'm trying to decide on going with the 60 qt. Megapots, but don't know if they will fit on the structure using Lonnie's plans.

Can anybody chime in on what they're using and whether Megapots will work?

I've also found a 60 qt. ss kettle on Amazon that 17 3/4" dia. for a great price, but I think it's too big?

Thanks in advance for any info. provided.

Great thread and forum by the way

~Rob

The beauty of the brutus is that you can do what ever you want with it. If you need the frame to be a different size to compensate for different diameter kettles, well the function will still work the same. Bring your pot to the welder and tell him to make the frame fit.

The megapots are not a good design for the Brutus because they are short and large in diameter. The 15 gallon kettle is 19" in diameter. The Brutus has a 16-16 1/2" span allowing a gap between pots that you will find necessary for lid management on some pots. The structure is designed to fit the Italian kettles of 14 gallons perfectly, but you can certainly modify for others.

Thanks Korndog for your input.

I like the look of the Italian kettles (tall and slender).

They cost more from NB and I don't know if there's a better deal anywhere on them. The Amazon 60 qt. stockpots are 16" tall and 17 3/4 wide, so not as bad.

I figure if I add 2" to the length and width on the frame in should accommodate them. Not as nice as the Blichmann's on your rig, but going stainless is the only big plurge I can do on this brew project.

I still can't believe SWMBO didn't veto this when she saw me reading about Brutus 10 in BYO.

The one area of the Brutus I haven't seen good pics of are the lids with the copper returns. Can anybody point me to pics?

Thanks!

Rob

The megapots are not a good design for the Brutus because they are short and large in diameter. The 15 gallon kettle is 19" in diameter. The Brutus has a 16-16 1/2" span allowing a gap between pots that you will find necessary for lid management on some pots. The structure is designed to fit the Italian kettles of 14 gallons perfectly, but you can certainly modify for others.

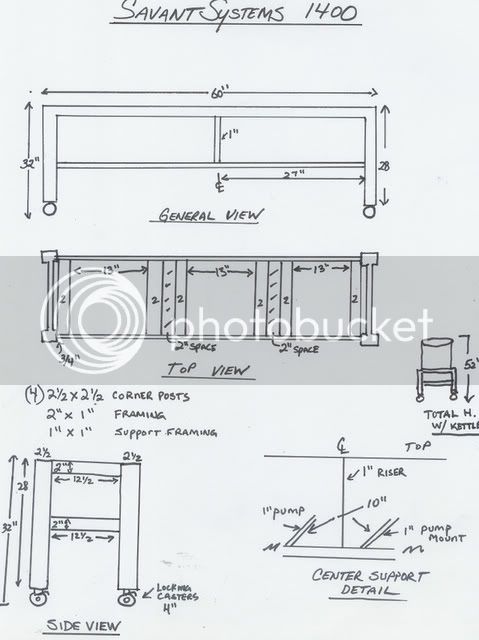

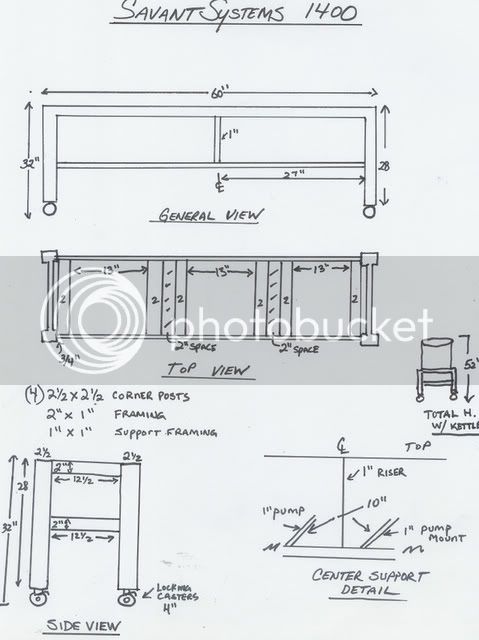

Here is a quick sketch of my dimensions, this is different than Brutus but will work well for Italian/Euro Kettles in 14 gallon :

Crap I don't have a name! I've been calling it the Brutus 10-DL but that is not catchy enough but works for now. There are a few minor things to finish but I've brewed on it twice so far and it has worked well.

A few small teaser shots and you can see the rest of them on my flickr page.

http://www.flickr.com/photos/brotherhoodbrew/sets/72157605889391749/

Damn nice looking Bro. Did you polish that stainless yourself or did you buy it brushed?

Her's the name I chose. I still have to do a better decal job though.

Bought it brushed. Saved me a lot of time.

Enter your email address to join: